“aira” Offers Automation And Manually Operated Metal Seated Floating Ball Valve Designed For Using In The Several Conditions Such As High Temperature & High Friction Fluids Of Oil & Gas, Petroleum, Petrochemical, Chemical Power Generation, Pulp & Paper, Mining Industry.

Specification & Standard

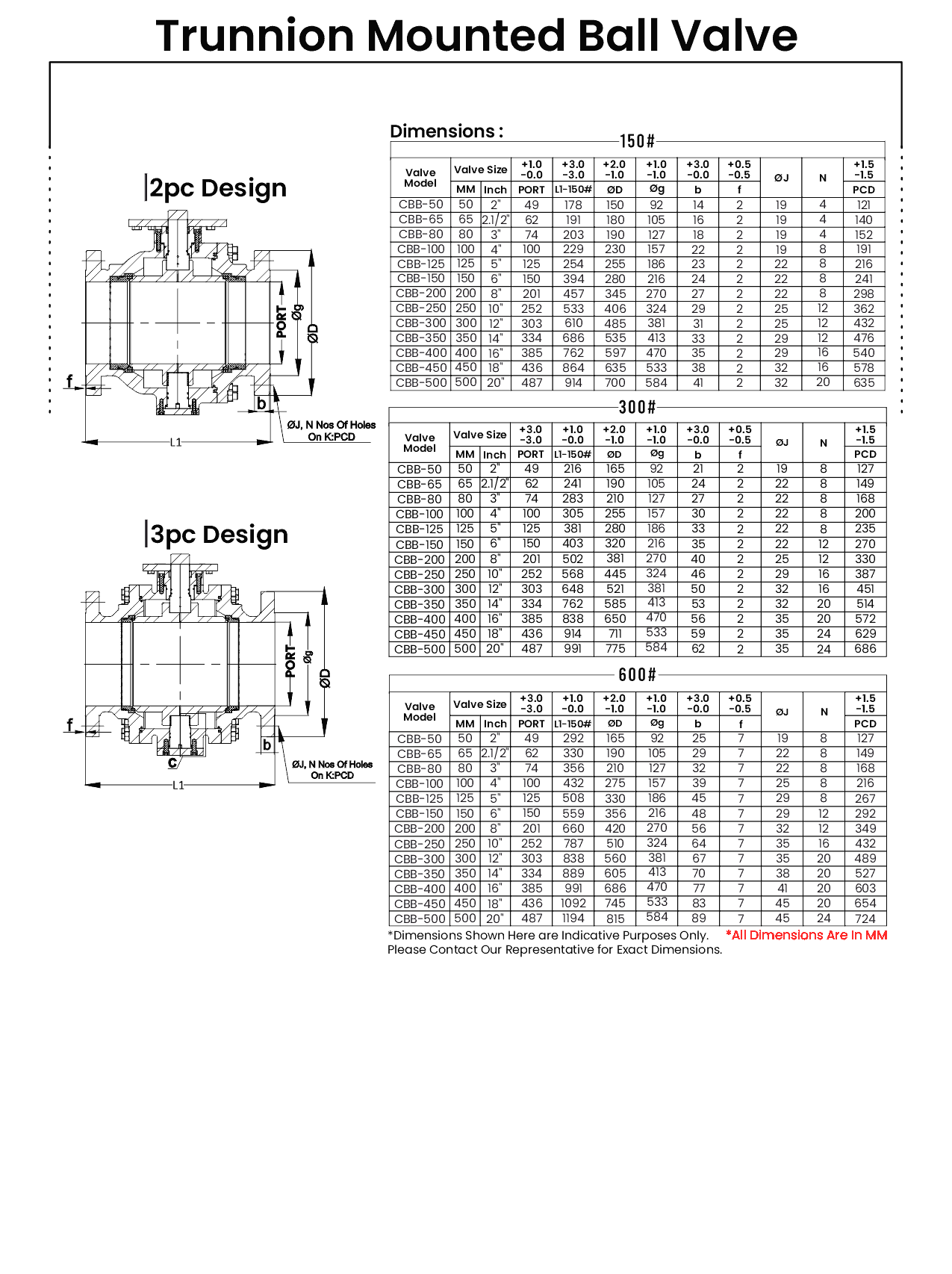

| Specification | Details |

|---|---|

| Basic Design | API 6D/ BS EN 17292 |

| Face To Face Dimensions | API 6D/ ASME B 16.10 – 150#/ 300#/ 600# |

| End Connection | ASME B 16.5 |

| Port Diameter | API 6D/ BS EN 17292 |

| Size Range | 2″ to 20″ Flanged |

| Temperature Range | PTFE: Upto 180°C |

| Pressure Class | 150#, 300#, 600# |

| Stem Material | AISI 410, SS 304, SS 316, SS 304L, SS 316L, DUPLEX 2205, DUPLEX 2507, MONEL |

| Seat Material | PTFE, RPTFE, CFT, GFT, MODIFIED PTFE, AIRA-250, NYLON, DEVLON, PEEK |

| Wall Thickness | ASME B16.34/ BS EN 17292/ BS EN-12516-2 |

| Fugitive Emission Testing | ISO 15848-1 |

| Fire Safe Testing | API 607 7th Edition |

| Media | Air/ Water/ Oil & Gas |

| Body Material | WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL, DUCTILE IRON, S.G IRON, INCONEL, LCB |

| Ball Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Ball Type | Solid Trunnion Mounted Ball Valve 150#/ 300#/ 600# |

| Flange Drilling | ASME B 16.5 Class 150# / 300# / 600# |

| Certification | Design CE Approved, POD, SIL 3, Fire Safe, API 6D, IBR |

There are no reviews yet.