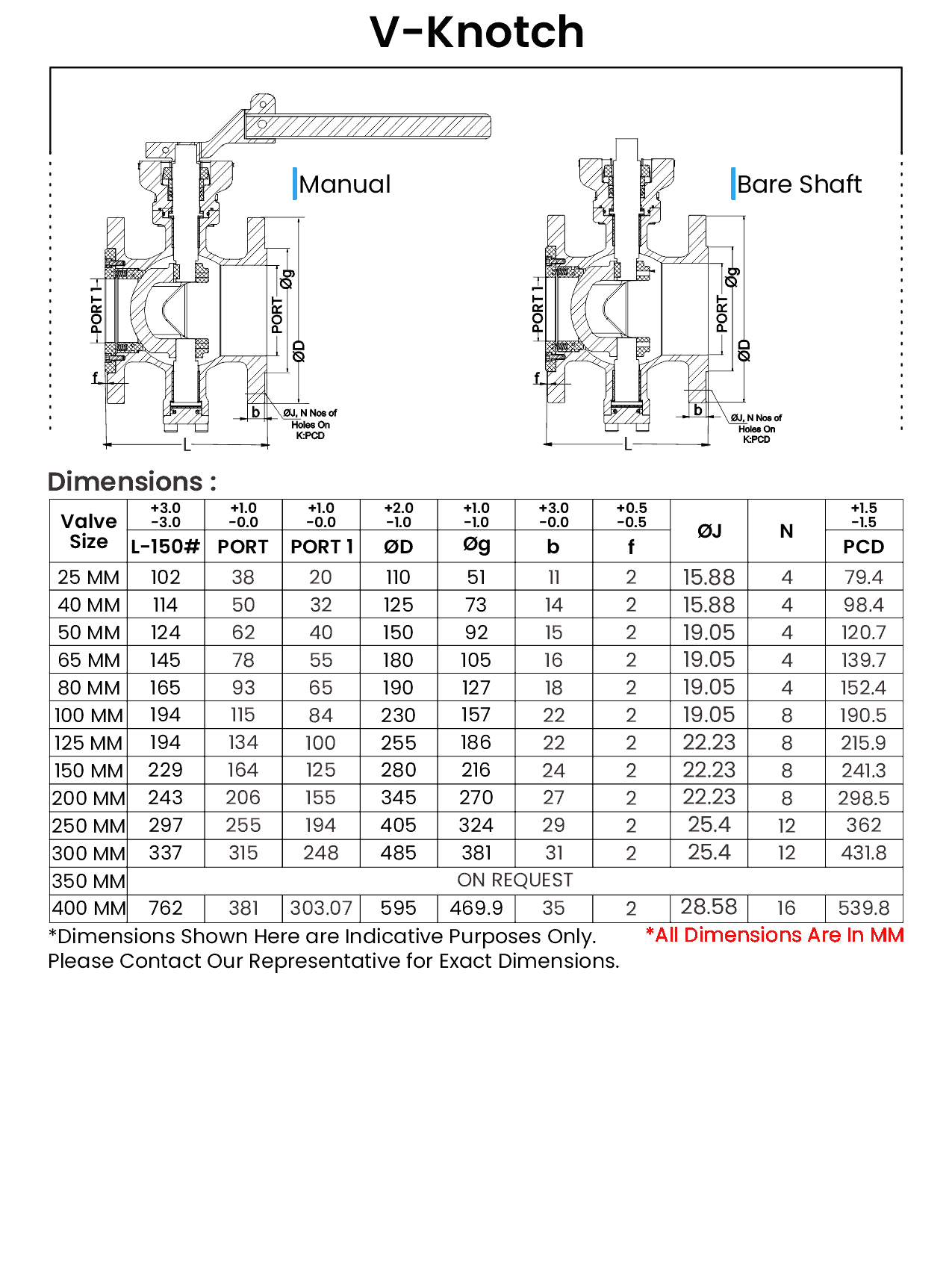

Aira Euro Automation is a manufacturer, exporter, and supplier of V Notch Ball Valve. V-Notch Ball valves are specially used to control the flow rate in pipelines because it has V-Notch inside the valve body. V Notch Ball Valve characterized V ball which is perfectly suited to give a full range of control applications with superior flow control. In small sizes, these control ball valves when compared to globe valves are more compact, lighter in weight, and much less expensive.

The V-Notch Ball Valve is also known as V Port Ball Valve and It can sustain up to 10Kg/Cm² pressure & temperature up to 180°C. We use PTFE seals, WCB/CF8/CF8M/CF3M materials used to make the Body, and CF8/CF8M/CF3M to make the Ball. Stainless Steel 304 has been used for the Gland plate, Gland L.N. Bolt, Trunnion pin, and bracket fitting bolts. For the Shaft and retainer, we use S.S. 304/S.S. 316. It has a class VI leakage type. It is available in 1” to 4” inches & has flanged ends 150# to 300#.

The 90 and 60 balls, like standard round hole balls, offer an equal percentage inherent flow characteristic. Medium angle V-Port 30 balls furnish a modified equal percentage inherent flow characteristic.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | BS EN ISO 17292 |

| Valve Face To Face Dimension | ANSI B16.10/ DIN 3202/ BS EN 558-1/2 |

| Flange Standard Conformity | ASME B16.5 150# |

| Size Range | 1″ To 16″ Flanged |

| Temperature Range | PTFE: Upto 180°C / RPTFE-200 |

| Pressure Class | 150#, 300# |

| Stem Material | CF3, CF3M, CF8, CF8M, 410, DUPLEX 2205, DUPLEX 2507, 17-4 PH |

| Seat Material | M TO M, PTFE, RPTFE, CFT, GFT, MODIFIED PTFE, AIRA-250, NYLON, DEVLON |

| Additional Features | Spring Loaded Design, Single Seated Design |

| Inspection & Testing | ASME/ FCI 70-2 Metal Seat For UNI-Direction Flow, Soft Seat |

| Top Flange Drilling | ASA 150#/ DIN 2632 & 2633/ BS EN 10 TABLE D,E,F (Customer Specified) |

| Media | Air/ Water/ Oil & Gas |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Ball Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Ball Type | Hollow & Solid |

| Flange Drilling | ASME B16.5 Class 150# |

| Certification | POD |

There are no reviews yet.